Showroom

Depending on the use and the kind of

material being polished, a polishing machine's precise design and parts may

change. Metals, polymers, glass, ceramics, and composites are just a few of the

many materials that can be polished with these machines due to their

adaptability.

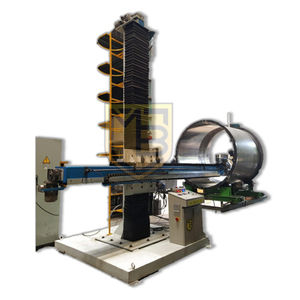

A Tank Polishing Machine is a tool used to

clean and polish tanks' metal surfaces, such as those on industrial tanks,

pressure vessels, and storage tanks. The machine uses a variety of techniques,

to clean the tank's surface of dirt, stains, rust, or other pollutants and

provide a polished and smooth finish.

The Pipe ID Polishing Machine is a

specialized tool used to clean and polish pipes' inner diameters. It is

intended to clean inside pipe surfaces of debris like dirt, scale, rust, or

other impurities and leave them looking smooth and polished. This machine is

very effective and economical to have.

A Centerless Polishing Machine is a

particular kind of tool used to polish and finish cylindrical workpieces

without the requirement for support or centering. To obtain a precise and

superior surface polish on cylindrical objects like tubes, bars, rods, and

shafts, it is frequently employed in manufacturing operations.

A Sheet Polishing Machine is an expert

tool used to polish and smooth the surfaces of sheets composed of different

materials. Construction, automotive, aerospace, and metal fabrication are among

the industries that frequently employ them. A big polishing drum with revolving

brushes, abrasive belts, or polishing pads makes up the typical machine.

Belt Polishing Machine may be constructed

from a variety of materials. The workpiece is held up against the moving

abrasive belt during the polishing procedure, which eliminates the material and

leaves the surface with a smooth, polished finish. To accommodate various

workpiece materials, the belt can be replaced or altered.

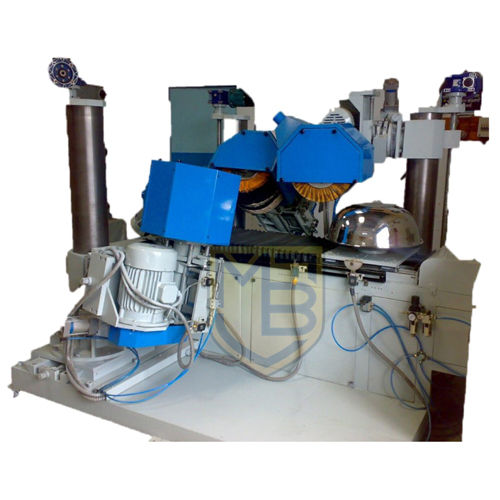

Cookware Polishing Machines can handle

different cookware items of all shapes and sizes and are effective for large

production. Cookware and media move and interact as a result of the drum's

rotation, removing flaws, smoothing surfaces, and improving the aesthetic of

the cookware.

Grinding Service can be applied to a workpiece to obtain a

clean and precise surface finish, eliminating abnormalities. This works well

for shaping workpieces into desired shapes by removing extra material or

reshaping them. Surfaces can be prepared for additional procedures by grinding

to create a smooth, evenly textured surface.

An Abrasive Belt Grinding Machine can

grind a variety of materials, including composites, plastics, wood, and metals.

Machines for grinding with an abrasive belt are adaptable and can be utilized

for a variety of tasks, including stock removal, surface grinding, edge

rounding, and deburring.

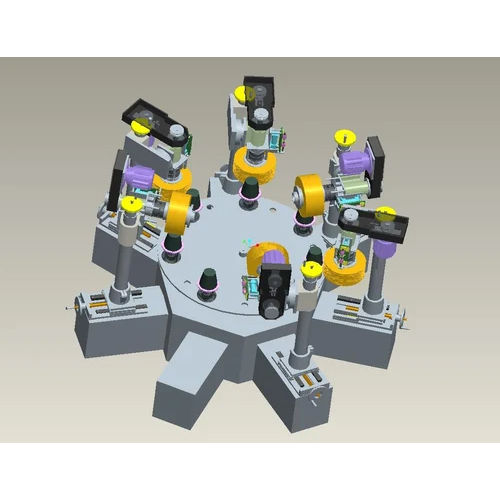

Deburring Machine is a specialized tool

that is used to clean the surface of a workpiece from burrs, jagged edges, or

rough protrusions. Burrs are undesirable components that can be produced during

manufacturing procedures. Depending on the individual needs and the kind of

workpiece being treated, they come in a variety of shapes and designs.

Buffing Machine is a polishing or buffing wheel, is a tool used to polish and improve the appearance of surfaces, usually composed of metal or wood. It is frequently used in fields including jewelry, woodworking, automobile, and others that call for a shiny and smooth finish.

|

M B TOOLS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese